>> Introduction / Content

Known Issues

The telemetry sensor doen’t always work as expected. The sensor might not give a signal. This is strange, knowing that we used the same part numbers in all cases. The way to solve this is drilling a 5mm hole, through the cover and take some of the material off the cover away with a bigger drill. The sensor should fit into this space. We will show pictures asap.

Below are links with examples. There is no specific preference for the suppliers.

In principle, it does not matter which vehicle is used as the basis.

The Traxxas x-maxx 8s is taken as an example because there is knowledge available about how to make it drive using digital instructions and it can carry some cargo. However, in principle, any vehicle can be used if it is drive by wire.

X-maxx 8S

The 8s is the largest Traxxas model, but much too fast and with minimal carrying capacity. To be able to carry more cargo, the vehicle must be converted so that the motors for steering and driving last longer.

For more information about the Traxxas, also see the relevant YouTube channel. You can search for the x-maxx there.

Prepare

The makeover is done in two main groups of activities:

- The cover, the wheels and the suspension will be dealt with on this page.

- The steering-servo, pinion, magnet and sensor, ESC on another page.

The change of the x-maxx is reversible. If you are ready these parts are left over:

- Original 4 springs

- Original receiver and antenne

- Original steering servo with the unused new arm and spring

- The cooler, you can use this but the robot isn’t using that much energy

- Original ESC

- Original pinion

- Unused parts that come with the magnet

- Unused parts that come with the sensor

Please note: Don’t use force to tighten screws!

Especially not in the plastic.

Using a drill will apply too much force. So stop immediately if a screw gives resistance.

Now, take off the body and the wheels.

Shocks and springs

Springs

Strong springs are needed. The strongest springs available from Traxxas are enough for loads up to about 2-6 kg, depending on the number of batteries on board.

The spring rate is just over 1.5.

Stronger springs are desirable.

Shock absorber oil

The shock absorber oil should be much more viscous than the standard oil. The syrupiness can be expressed, among other things, in cSt (centistoker). We use 1,000 cSt in the shock absorbers.

Example

Instruction

For the replacement of the shocks’ oil and suspension springs there are several videos on the internet. There is a Traxxas shock and suspension maintenance video.

This one looks fine for replacing the suspension and oil.

Some differences:

- For both front and back shocks oil with cSt 1.000 is used.

- You don’t have to remove the wheels although this seems to be handy.

- To allow for carrying goods the strongest springs are used.

- The springs are set as short as possible by turning the ring on the shock.

- Shock-socks are nice but not on our list.

Note:

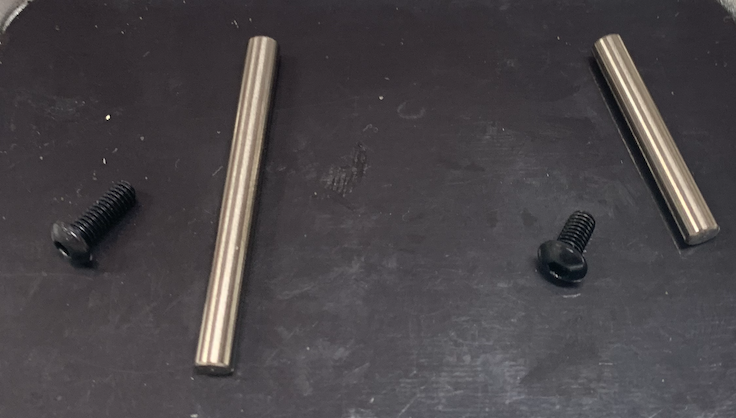

- The marks on the new spring should be on top

- The short bolt comes with the short pin

There is nothing special to mention here. Just follow the instruction on the video.

When done move on to the next stage.

0.6-2004111255 Issue with sensor, spur is off parts list

0.5-2004081538

0.4-2004061732 New description

0.3-2004061628 Spur in review, other Wago-connectors

0.2 2003281657 Video example ESC

0.1 2003262346